Login

Contact

Description

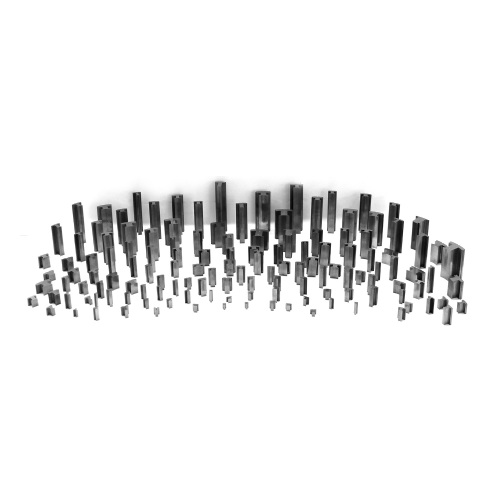

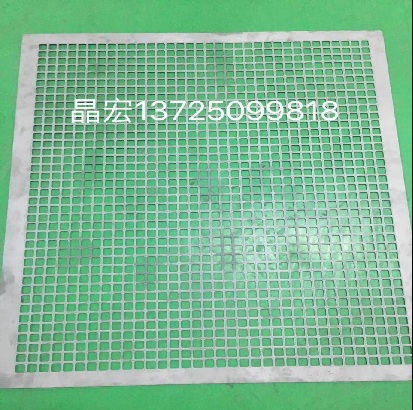

The stepper motor core is superimposed by large rotation, which offsets the problem of the same plate difference on the material, and makes the parameters of parallelism, flatness and dynamic balance of the end runout rotor of the product achieve the ideal effect of customers. At present, the annual output of stepper motor core reaches 45 million sets of fixed rotor core, and the products are widely used in industrial automation, office automation, printing equipment, household appliances, monitoring equipment, medical equipment, stage lighting and so on.

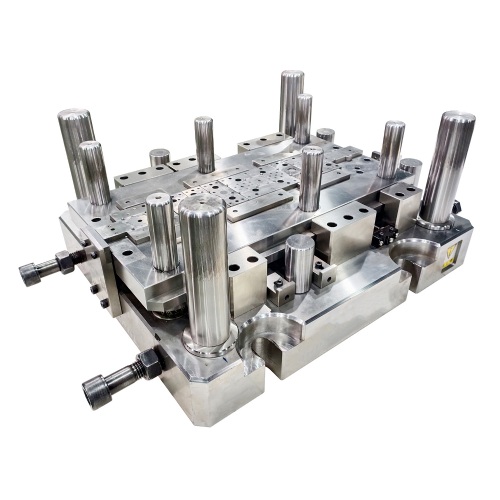

In the new product research and development, the Royal Horse Club to customer needs, from the product tooth shape/groove/inner hole and other aspects of continuous optimization, in order to get better quality new products. At the same time, through the optimization of products, constantly improve the cost performance of products.

In the new product research and development, the Royal Horse Club to customer needs, from the product tooth shape/groove/inner hole and other aspects of continuous optimization, in order to get better quality new products. At the same time, through the optimization of products, constantly improve the cost performance of products.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry