Bender | Green hydrogen - electrically safe

Date: 2025-02-09

BENDER GMBH & CO. KG

Booth No: A322

Green hydrogen - electrically safe

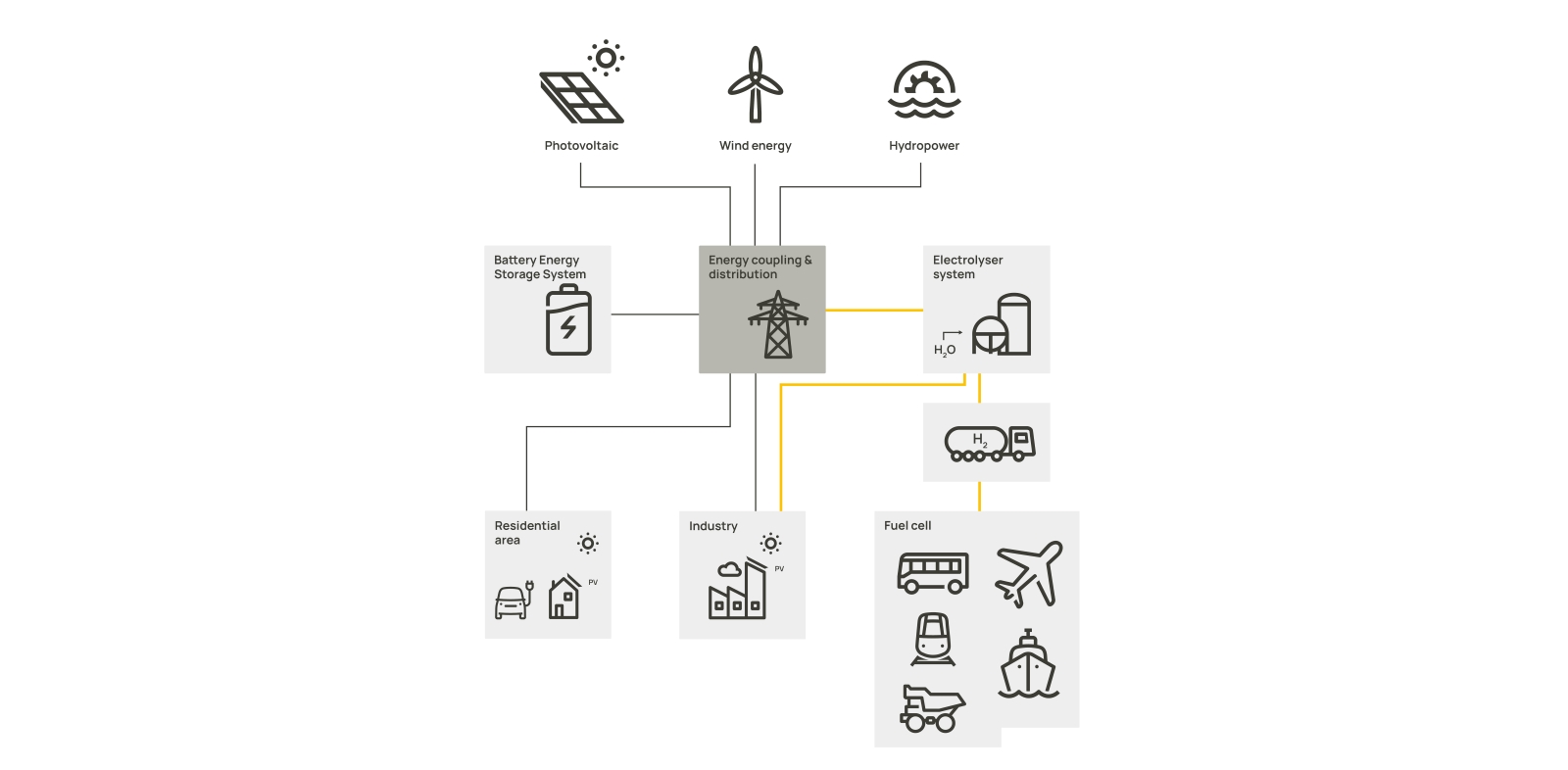

Energy sources of the future

Everybody is talking about hydrogen. This is because hydrogen is regarded as an ideal energy carrier and energy storage medium. It therefore plays an important role in the energy transition.

Green hydrogen is needed in particular. Green hydrogen is produced using renewable energies emissions-free and can be converted back into electrical energy just as emission-free.

However, in order to meet the growing demand for hydrogen, a number of challenges still need to be overcome, e.g. on issues of electrical safety. Bender offers its expertise here to support you with your hydrogen applications.

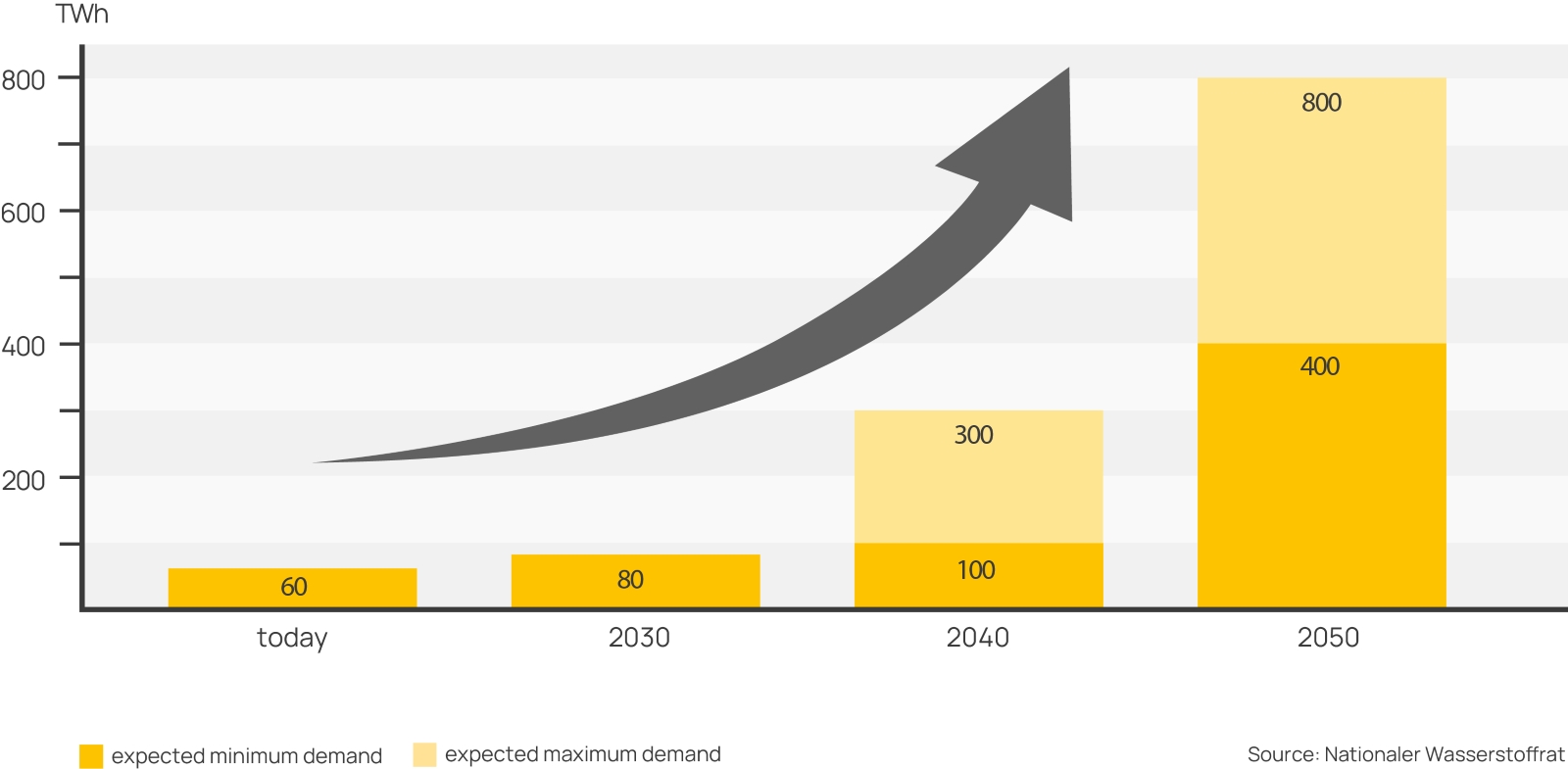

Growing hydrogen demand

In Germany alone, demand will rise from the current 55 TWh to up to 800 TWh in 2050 (see infographic). The production of green hydrogen requires a great deal of energy from the sun, wind and water. However, the electrolysis capacity installed to date is too low to meet the demand of 100 TWh or 3 million tonnes of hydrogen in 2030. Many more electrolysis plants are therefore needed.

Demand of hydrogen in Germany today and tomorrow

The challenge of electrical safety

A high level of electrical energy is required for hydrogen production using electrolysis. Electricity is generated when hydrogen is utilised in fuel cells.

People and systems must be protected from the dangers of electric current. The technical challenges for the safe operation of electrolysers and fuel cells are considerable. Particularly in electrolysis systems, there are currently areas that are not described in a standard or safety regulation. For this reason, a customised safety concept must currently be developed for each project.

To ensure that the goals of the hydrogen ramp-up can be achieved, Bender is working with partners from industry and science to contribute to the creation of a standard for the electrical safety of electrolysers.

Electrolysis

During electrolysis, water is broken down into its two components, hydrogen and oxygen, using an electric current. Depending on the size of the electrolysis systems used, very high currents flow (sometimes in the kA range). Due to these high currents, special safety requirements are placed on electrolysis systems.

Fuel cells

In fuel cells, hydrogen is converted into electricity with the addition of oxygen. Therefore, the relevant standards and regulations for the safe operation of electrical systems must be observed when using fuel cells. The requirements vary depending on the design and intended use of the fuel cells.

For electrically safe and reliable operation of electrolysers and fuel cells, it is advisable to plan for permanent insulation fault and residual current monitoring from the outset when planning the system. Only permanent monitoring for insulation faults and residual currents can guarantee safe and predictable operation.

Solutions for smart and safer electrical systems

For more than 75 years, Bender has been a pioneer and market leader for solutions that make electricity intelligent and safer. Our experience and mature technologies have played an important role in the technical developments of recent years and decades. For example, in the transformation of the energy sector and electromobility.

Bender also offers solutions for electrically safe operation in the field of hydrogen production and utilisation. We are also actively involved in the relevant standardisation committees in order to create the framework conditions required for the development and production of safe hydrogen applications.

Where we support you with your hydrogen application

-

Customised solutions and concepts

-

Implementation of a holistic safety concept with the following components of the protection objectives:

-

System protection

-

Protection against thermal effects

-

Protection against the dangers of electricity

-

- System availability as an integral part of the protection goals

- System expansion and scaling effects

- Selection of the correct and consistent grid form (earthed or unearthed)

- Insulation fault and residual current monitoring

- Early detection of asymmetries in the electrical supply to prevent excessive equalising currents

Visit us at Intelligent Asia Thailand 2025:

📍Booth #A340 BITEC, Bangkok, Thailand

📅 6 - 8 March 2025

For further information, please read our brochure from the link below.

More Press Release

| 2025-02-27 |

PMT Solutions for Printed Circuit Board and Electronics Industry.

NICHE TECH (2004)CO.,LTD

|

| 2025-02-27 |

PMT Global : PCB INSPECTOR

NICHE TECH (2004)CO.,LTD

|

| 2025-02-27 |

HIGH-SPEED WAFER FEEDER

NICHE TECH (2004)CO.,LTD

|

| 2025-02-25 |

Intelligent Asia Thailand 2025 - SCREEN GP (Thailand) Co.,Ltd.

SCREEN GP (THAILAND) CO., LTD.

|

| 2025-02-18 |

Pilz will be at SPS Stage Bangkok 2025

PILZ SOUTH EAST ASIA (THAILAND) CO., LTD.

|

| 2025-02-18 |

Polar GmbH: RITS550/RITS880 – Automated Impedance Measurement System

SPS INTERTECHNOLOGY CO., LTD.

|

| 2025-02-11 |

🇹🇭✨【探索智慧製造新未來!Shape the Future of Smart Manufacturing with Us!】✨🇹🇭 🚨 環球集團邀您共襄盛舉:2025年泰國電子智慧製造系列

WORLD WIDE PCB EQUIPMENTS CO., LTD.

|

| 2025-02-09 |

Bender | The new ISOMETER® iso175

BENDER GMBH & CO. KG

|

| 2025-02-04 |

We will be at the 2025 Intelligent Asia Thailand exhibition from March 6 to 8.

ENRWEY CO., LTD.

|

| 2025-02-04 |

We're here 2025 CES.

ENRWEY CO., LTD.

|

| 2025-01-30 |

VCP Line (Vertical Continuous Plating Line)

PATA CHEMICALS AND MACHINERY CO., LTD.

|

| 2025-01-30 |

ENEPIG / IGEPIG Process

PATA CHEMICALS AND MACHINERY CO., LTD.

|

| 2025-01-30 |

Wastewater Treatment

PATA CHEMICALS AND MACHINERY CO., LTD.

|

| 2025-01-28 |

Teflon Heat Resistant Tape-NO 424

FUHE POLYMER MATERIALS SCIENCE CO., LTD.

|

| 2025-01-28 |

FH-NO-920: Teflon coated fiberglass heat resistant cloth

FUHE POLYMER MATERIALS SCIENCE CO., LTD.

|

| 2025-01-28 |

Teflon heat resistant conveyor belt

FUHE POLYMER MATERIALS SCIENCE CO., LTD.

|

| 2025-01-24 |

The UR30 Heavy payload, compact cobot

UNITED PERCISION TECHNOLOGY CO., LTD.

|

| 2025-01-24 |

PALLETIZING SOLUTION

UNITED PERCISION TECHNOLOGY CO., LTD.

|

| 2025-01-24 |

ทำไมต้องใช้ UNIVERSAL ROBOTS เท่านั้น...!!!

UNITED PERCISION TECHNOLOGY CO., LTD.

|

| 2025-01-21 |

菲爾特客製濾材 獲大廠採用

MICROTECK CORP.

|

Exhibitor Inquiry

Exhibitor Inquiry