Login

Contact

Description

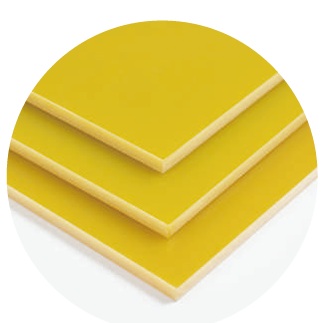

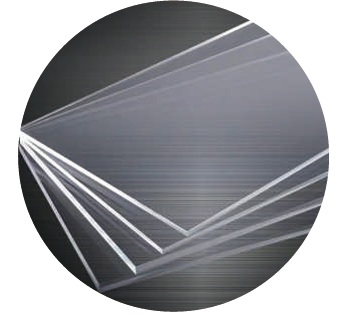

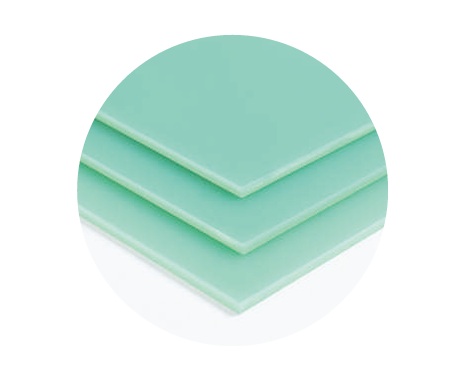

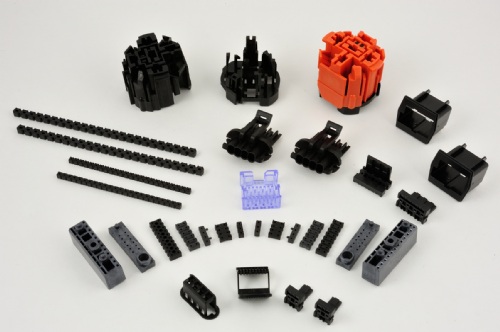

Low pressure molding production is a process that uses hot liquid (hot melt) polyamide material and operates at very low molding pressures ranging from 20 to 500 psi. This process provides excellent dustproof, waterproof, and moisture-proof performance while protecting sensitive electronic components. Compared to conventional potting processes, low pressure molding offers a significantly shorter cycle time, with LPM molding cycles of approximately 16–60 seconds versus 8–24 hours for potting. The LPM raw materials are RoHS compliant and suitable for applications such as insert molding, PCB overmolding, waterproof cable overmolding, and waterproof micro switch encapsulation. For more information: https://kingsmachinery.com.tw/en/category/Low-Pressure-Injection-Molding-Turn-Key-Solution.html

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry