登入

聯絡我們

產品特色

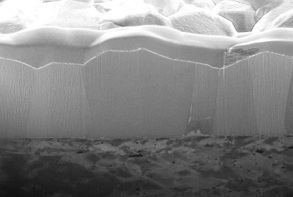

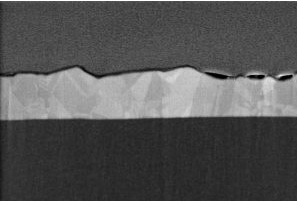

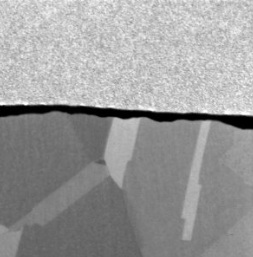

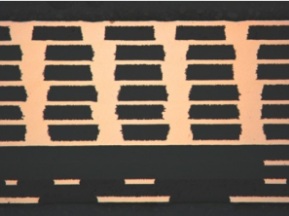

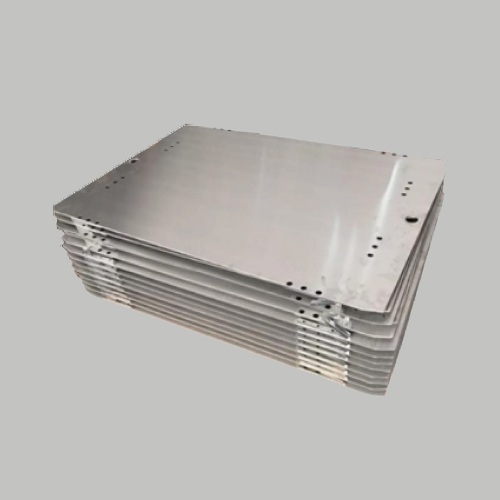

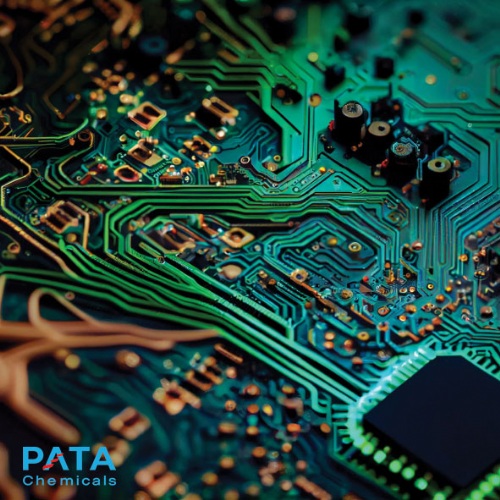

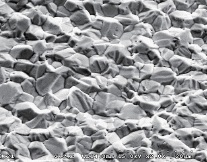

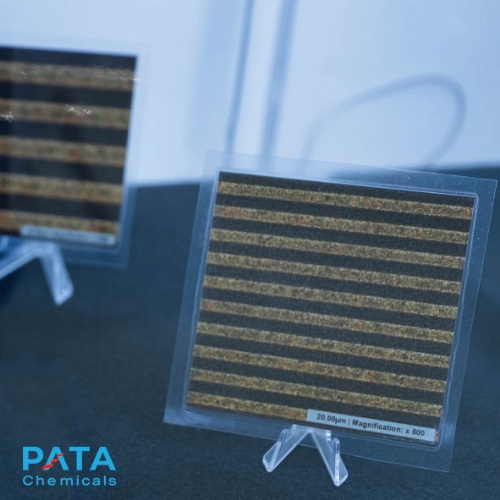

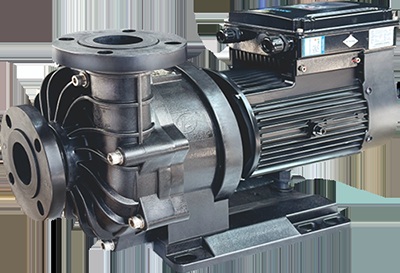

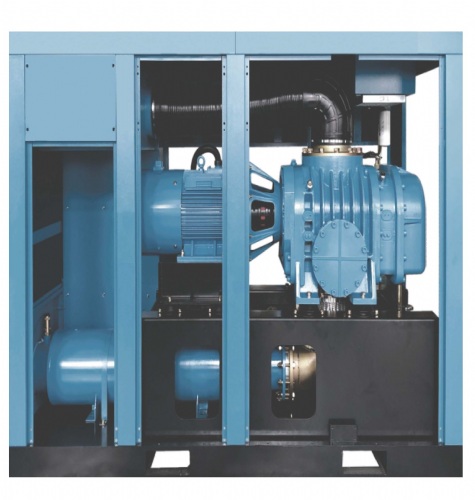

The Stannatech LINE is a next generation immersion tin system, built on the foundation of over 110 installations for high-end PCB production. Specifically designed to meet the demanding standards of the automotive industry, this line integrates proven mass production features such as a fluid delivery system and ancillary equipment (Constanic and Crystallizer) with a redesigned process module layout, transport systems and improved rinse technology. The result is superior quality and cost efficiency with significant chemical savings.

With the Stannatech LINE, we offer a comprehensive solution of equipment, software and chemistry from a single source, potentially reducing costs by up to 30%. In addition, the system can reduce water, energy and chemical consumption by up to 90%, making it a very environmentally friendly choice.

With the Stannatech LINE, we offer a comprehensive solution of equipment, software and chemistry from a single source, potentially reducing costs by up to 30%. In addition, the system can reduce water, energy and chemical consumption by up to 90%, making it a very environmentally friendly choice.

您可能也感興趣

人氣產品專區

回上頁

立即詢問

立即詢問