登入

聯絡我們

產品特色

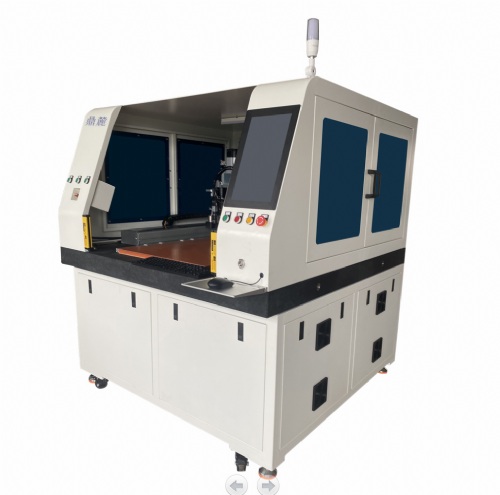

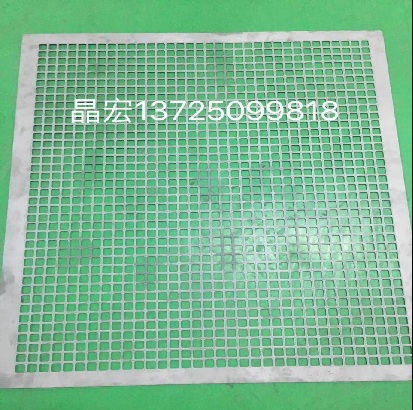

1、 Use vector file (xY) to setthe standard coordinatesforthe drillingofthesemi-solidifiedpiece, then the control system will send the specific data to the machining axis, and themachining axis will move according to the specified coordinates to achieve thepurpose of processing;

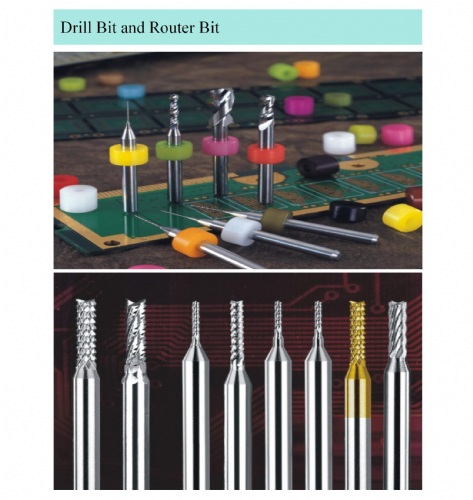

2、inputtheinformationrelatedtotheproductionofstandard coordinate aperture,size andproductionmaterialnumberintothedrillingmachineasrelevantconditions for processing;3. Make preparations before production, such as loading the plate, preparing the drill bitdrillingandexecutingcoordinatecommands;

4、Drill bitdrillingnumberWarning:Setthedrillbitdrillingnumber,automatic alarm when itarrivesWith safetyprotectiongrating,emergencystopswitch,safeand reliable operation;5,The machine is equipped with automatic circulatingwater system coolingspindle (withtemperaturedetection,and overheatingprotection alarm) ;

2、inputtheinformationrelatedtotheproductionofstandard coordinate aperture,size andproductionmaterialnumberintothedrillingmachineasrelevantconditions for processing;3. Make preparations before production, such as loading the plate, preparing the drill bitdrillingandexecutingcoordinatecommands;

4、Drill bitdrillingnumberWarning:Setthedrillbitdrillingnumber,automatic alarm when itarrivesWith safetyprotectiongrating,emergencystopswitch,safeand reliable operation;5,The machine is equipped with automatic circulatingwater system coolingspindle (withtemperaturedetection,and overheatingprotection alarm) ;

您可能也感興趣

人氣產品專區

回上頁

立即詢問

立即詢問