Login

Contact

Description

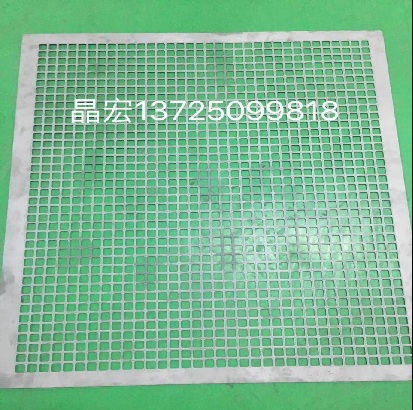

一.Product description

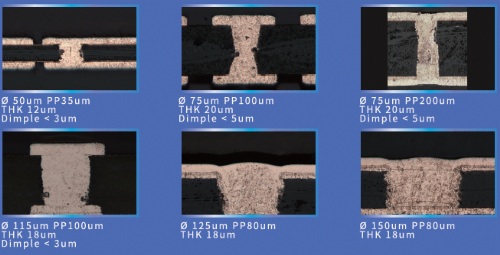

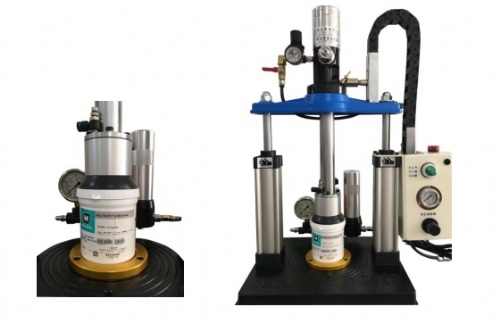

The release agent is to prevent the molded composite products from sticking to the mold, and a kind of separator film is applied between the product and the mold, so that the product can easily come out of the mold, and at the same time ensure the surface quality of the product and the mold intact. The AXE-188 product developed by our company is mainly used in hardware, injection molding, PCB industry and other fields, and the PCB industry is used as a release agent for pressing plates in the pressing process to prevent PP residual rubber particles and improve product quality.

二.product advantages

1. Simple operation, easy to clean, no residue;

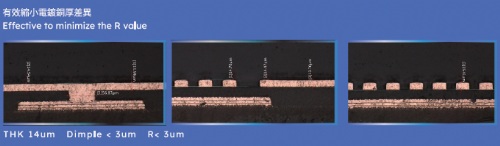

2. Improve product quality;

3. Save manual grinding plate operation and reduce costs;

4. Reduce and delay the maintenance time, and it is not easy to produce annular subsidence and crystallization.

The release agent is to prevent the molded composite products from sticking to the mold, and a kind of separator film is applied between the product and the mold, so that the product can easily come out of the mold, and at the same time ensure the surface quality of the product and the mold intact. The AXE-188 product developed by our company is mainly used in hardware, injection molding, PCB industry and other fields, and the PCB industry is used as a release agent for pressing plates in the pressing process to prevent PP residual rubber particles and improve product quality.

二.product advantages

1. Simple operation, easy to clean, no residue;

2. Improve product quality;

3. Save manual grinding plate operation and reduce costs;

4. Reduce and delay the maintenance time, and it is not easy to produce annular subsidence and crystallization.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry